| Category: | Sieve Bend Screen |

| Material: | stainless steel 302,304,316,316L |

| Properties: | wedge wire screen |

| Application: | solid-liquid separation and recovery. Especially for beer waste water, papermaking wastewater, slaughtering waste water, juice processing wastewater |

UBO wedge wire Screens is the top producer of SS Vee-wire dewatering gravity screen in the China. UBO wedge wire screen is a Chinese leader in fine wire screening applications and supply dewatering screens to many of the OEM's.

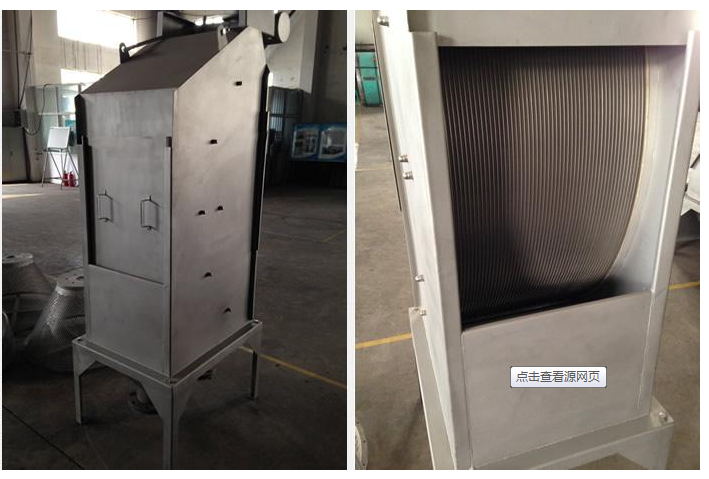

SS Vee-wire dewatering gravity screen sieve bend screen, also called Wedge wire curved screen , Gravity sieve screen , sieve bend screen, DSM screen, pressure curved sieve screen. It is a new type of high efficiency still screening equipment. They often used in corn starch equipment. Its working principle is under the action of gravity through the sieve surface of the cutting effect of the need to deal with the separation of materials. The working part is composed of stainless steel wedge wire screen sieve, showing a certain degree of curvature of the concave sieve surface, can be applied to high-throughput wet material screening occasions, the material screening, separation, dehydration, washing with the extraction and solid impurities And so on. This equipment is used in the starch industry, corn dehydration, germ dehydration and washing, coarse residue fiber separation, they are welcomed by users. The gravity sieve screen is the ideal screening equipment in the starch industry. The equipment has high yield, good filtration effect, the use of safe and reliable, screening is not easy to blocked, and long service life, long life equipment, no wearing parts, reasonable structure, beautiful appearance, small footprint. Also according to different uses can be divided into multi-stage sieve, they can also be used in combination with the pressure screen.

Gravity screen is a new, efficient, and static screening device, the main working part is the wedge wire sieve bend screen. Which is made of stainless steel wedge rods, was a certain degree of curvature of the concave sieve surface. The gravity screen could be applied to the high processing capacity of wet material screening occasions, a variety of materials separation, screening and dehydration, washing, and extraction and removal of solid impurities, the body for the starch industry, corn dehydration, germ dehydration and washing , Coarse residue (fiber) separation, has been widely used, welcomed by users, called the starch industry is an ideal screening equipment, can also be used for other industries.

The equipment has high yield, good screening effect, the use of safe and reliable, screening does not plug the advantages, and equipment long life, no moving parts, reasonable structure, beautiful appearance, small footprint.

· Fine Wire

· Small tolerance

· World leader

· Alloy Selection

|

Specification |

|

|

Material: |

AISI304/316/316L,Galvanized low carton. |

|

Wedge Wire (mm): |

Width : 1.50 1.80 2.30 3.00 3.30 3.70 |

|

Height : 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

|

Support Rod (mm): |

Width : 2.30 3.00 3.30 3.70 |

|

Height : 2.70 3.60 4.70 5.60 6.30 |

|

|

Round : 2.50mm -- 6.0mm |

|

|

Slot / Opening Size |

0.10 -- 6.00mm ,also can be customized as your request. |

|

Lengt/Width |

Can be customized as your request |

|

Diameter |

25mm -- 1200mm. |

|

Note:Other specifications can be customized according to your requirement. |

|