| Category: | Wedge Wire Screen Cylinders |

| Material: | Low carton, low carton galvanized steel (LCG), stainless steel (304,316etc.) |

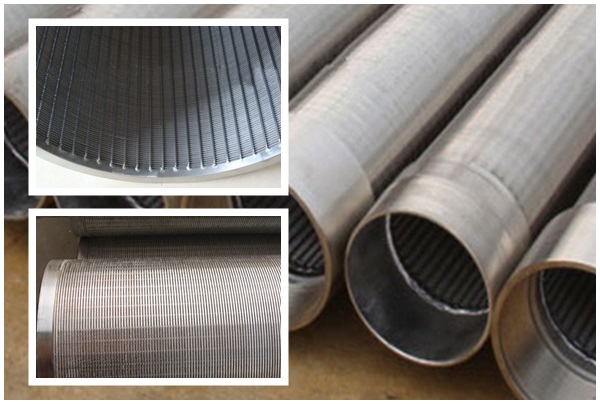

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

Slot opening for stainless steel water well screens are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be cleaned and free of burrs and cuttings.

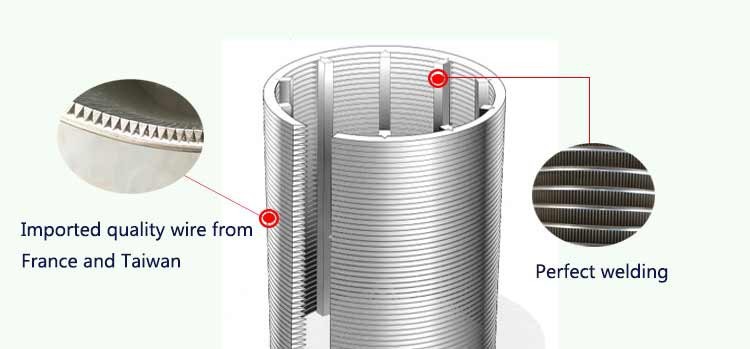

Each slot opening between adjacent wires is V-shaped, from the special shape of wire used to form the screen surface. The V-shaped openings designed to be non clogging, are narrowest at the outer face and widen inwardly.

Oil well , water well ,deep well , geothermal well,control sand,liquid solids separation,water treatment,waste water treatment,filter element,the industrial wastewater treatment plants,dewatering equipment,power plant,chemical plant,dehydrate ,steel plant,nuclear power plant ,Pharmaceutical factory ,coal mine,The fixed double chamber bed anion, cation exchanger ,Anion exchanger,waste water treatment system, Sea Water Desalination ,industrial and municipal Water ,Wastewater Treatment plants,drinking water treatment,potable water treatment,purified water treatment,boiler water treatment,boiler water conditioning,resin water treatment,Softening water treatment equipment ,wastewater treatment,sewage treatment,Composite ion exchanger.

1. Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2. Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3. Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

4. Low operational costs: Large open area with an effective flow, high yield and a low pressure drop .

5. Long life: Welded at each intersection creating a strong and durable screen.

6. Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

7. Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.

Each slot opening between adjacent wires is V-shaped, resulting from the special shape of the wire used to form the screen surface. The V-shaped opening, designed to be non clogging, are narrowest at the outer face and widen inwardly.

Wedge Wire thread stainless steel water well screens provide more intake area per unit area of screen surface than any other type. For any given slot size, this kind of water well screen has maximum open area.

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |