| Category: | Wedge Wire Screen Cylinders |

| Material: | Stainless steel |

| Properties: | Stainless Steel |

| Application: | Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc |

Stainless steel Casing pipe & tube are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Used in industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc.

Used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by dramatically reducing the load.

Used for fiber removal in Starch industry.

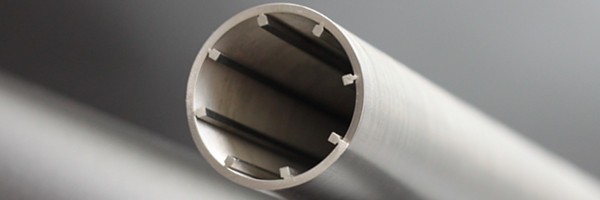

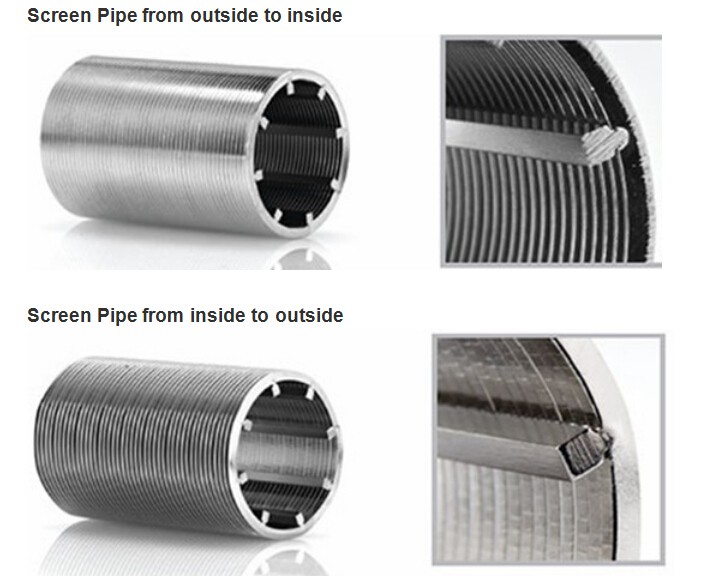

The Wedge Wire Screen is composed of rod strips and V shaped wires through manufacturing on specialized welding machine. The rib strips and V shaped wires will be welded by resistance welding, has enough welding strength, equally slot gap, high corrosion resistance, large filter area, good permeability, simple structure

1. It has high mechanical strength, can bear large pressure drop.

2. It has equal slots for filtering, can form equally distributed filter cake, easy to clean for reuse.

3. The wedge type slot can improve backflushing and regeneration performance.

4. It has resistance to pressure, temperature, aging, corrosion, can be applied for different kinds of fluid.

The design is customized to your demands;

Slot opening from 50 micron up to 2000 micron

All API and ANSI pipe sizes are available

Customized construction:

Lower V-wires for reduced OD

Higher support rods for more standoff

Customized end-fittings and threaded connections

Fixation of screen by welding or shrink fitting of end-rings to the base-pipe

|

Outside Diameter

|

Profile wire

|

Rod wire

|

Rod quantity

|

Slot size

|

Length

|

||

|

DN

|

Inch

|

mm

|

mm

|

mm

|

|

mm

|

mm

|

|

20

|

3/4

|

26.9

|

1.5*2

|

2*3

|

12

|

0.1~0.25

|

45~3000 |

|

25

|

1

|

33.7

|

1.5*2

|

2*3

|

14

|

0.1~0.25

|

45~3000 |

|

32

|

1-1/4

|

42.4

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000 |

|

40

|

1-1/2

|

48.3

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000 |

|

50

|

2

|

60.3

|

1.5*2

|

2*3

|

18

|

0.1~0.5

|

45~3000 |

|

65

|

2-1/23

|

76.1

|

1.5*2

|

2*3

|

20

|

0.1~0.5

|

45~3000 |

|

80

|

3

|

88.9

|

1.8*2.5

|

2*3

|

24

|

0.1~0.5

|

1000~6000 |

|

100

|

4

|

114.3

|

1.8*2.5

|

2*3

|

30

|

0.5~2

|

1000~6000 |

|

125

|

5

|

139.7

|

2.3*2.7

|

2*3

|

36

|

0.5~2

|

1000~6000 |

|

150

|

6

|

168.3

|

2.3*2.7

|

3*5

|

44

|

0.5~2

|

1000~6000 |

|

200

|

8

|

219.1

|

3.3*3.5

|

3*4.7

|

56

|

0.5~2

|

1000~6000 |

|

250

|

10

|

273

|

3.3*3.5

|

4*6

|

66

|

0.5~2

|

1000~6000 |

|

300

|

12

|

323.9

|

3.3*4.7

|

4*6

|

72

|

0.5~2

|

1000~6000 |

|

350

|

14

|

355.6

|

3.7*5

|

4*6

|

80

|

0.5~2

|

1000~6000 |

|

400

|

16

|

406.4

|

1.5*2

|

2*3

|

94

|

0.1*2

|

1000~6000 |

|

450

|

18

|

457

|

2*3

|

4*5

|

112

|

0.1*2

|

500~400 |

|

500

|

20

|

508

|

2*3

|

4*5

|

124

|

0.1*2

|

500~400 |

|

550

|

22

|

559

|

2*3

|

4*5

|

140

|

0.1*2

|

500~400 |

|

600

|

24

|

610

|

2*3

|

4*5

|

156

|

0.1*2

|

500~400 |

|

Siot:0.1mm~2mm Tolerance:0.05 |

|||||||