| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel |

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

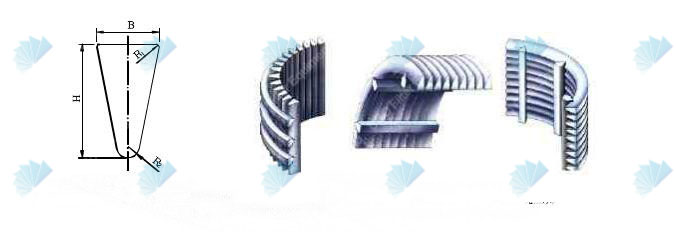

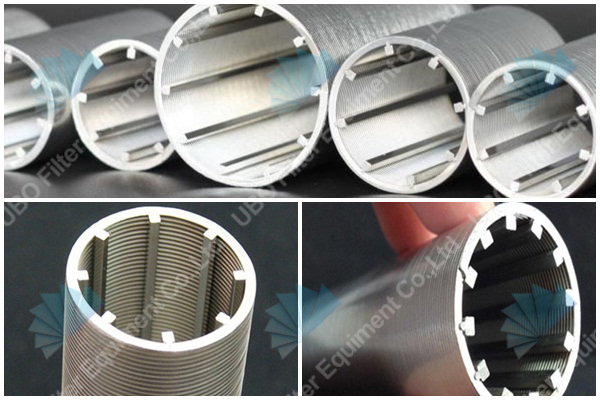

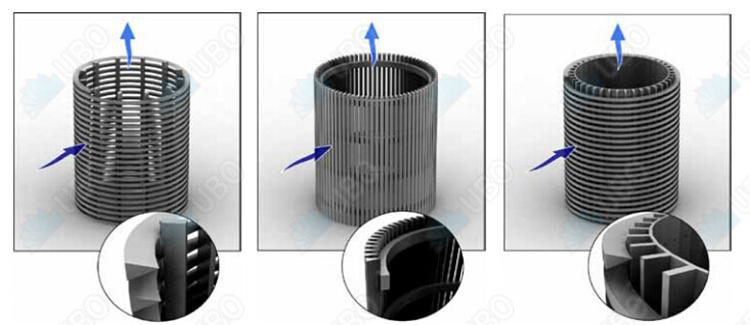

This type of stainless steel anti-sand screen pipe is constructed by winding cold rolled triangular V-shaped wire around a circular array of longitudinal rods. the wire is welded to the rods and produces a rigid unit that has high strength and minimum weight.

The screen can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen's construction.

-- Beverage industry

-- Oil, cooling liquids & fuel filtration

-- Chemical industry

-- Water purification

-- power plants

-- mechanical engineering

1) Non-clogging construction: The V-shape section plane of wedge wire screens (Wedge Wire type screens) creates the continuous slot, which can avoid blockage and make sure of the unimpeded water.

2) Large Filtering Area: The consecutive slot of wedge wire screens (Wedge Wire type screens) have wider open area,

and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can control sand better, which can increase the water yield and prolong service time of the well.

3) Long service life Wire and support rods are all-welded, which makes wedge wire screens (Wedge Wire types screens) more robust and longer life.

4) Excellent construction strength: The longitudinal support rods and the continuous slot make the wedge wire screens(Wedge Wire type screens) have more excellent pressure-resistant performance.

5) Specifications and end connections of wedge wire screens(Wedge Wire Screens) can me fabricated according to customers’ requirements.

|

Wire Size |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 |

|

|

Support Rods |

Width(mm): 2.30 3.00 3.30 3.70 |

|

|

Note: other wires and rods available upon request |

||

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

|

Material: |

Low carton, low carton galvanized steel (LCG), stainless steel (304,316 etc.) |

|

|

Length |

Lengths up to 6 meters. |

|

|

Diameter |

ranging from 25mm to 800mm. |

|

|

End connection |

Plain beveled ends for butt welding or threaded |

|