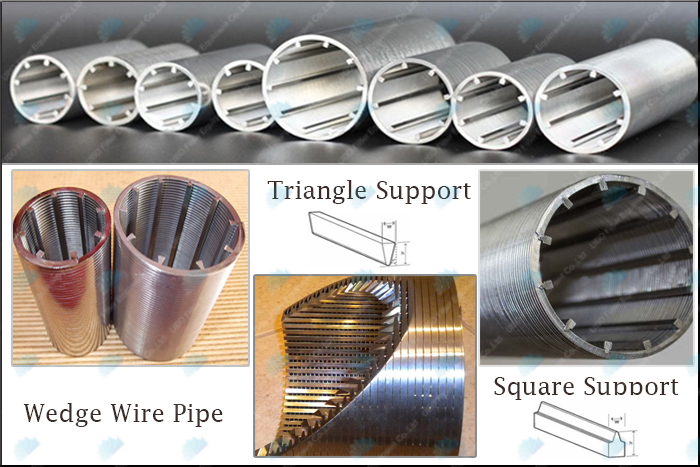

| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Wedge Wire Screen |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

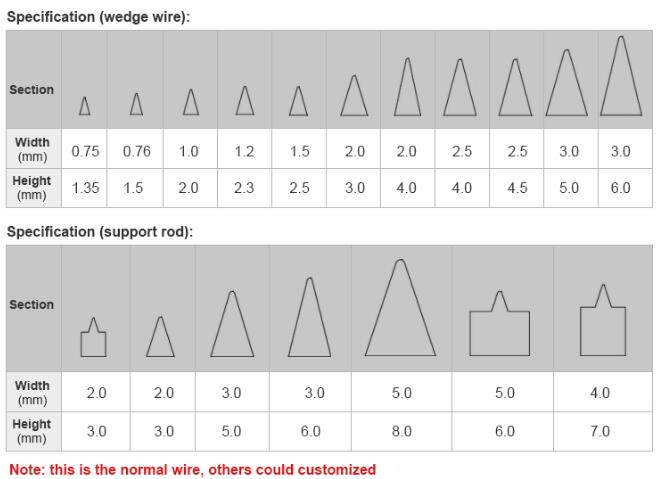

stainless steel Water treatment products water filters is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). It has a structure and high open area, as well as accurate slot dimension.

This filter is applied to oil sol ution containing wax oil and asphalt or with high viscosity, it is widely applied in water treatment coarse and precise filtration of various industries, such as, power oil wells, gas wells, chem ical, mining, paper making, environmental protection, metallurgy, sand—proof, decorative.

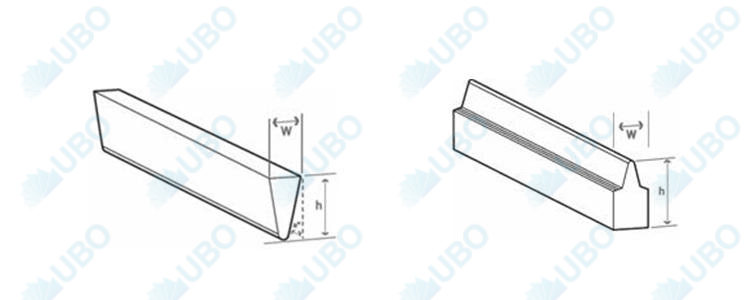

V-Shaped Slots: Openings shaped like a "v" that open toward the inside of the well tend to allow the particles that are just barely smaller than the width of the slot pass. In other shapes of openings, these particles would get caught in the screen and clog it.

Continuous Slots: The special design gives continuous slot opening across the periphery and length of screen.

Very Large Open Area: This design gives continuous slot and hence the% open area for water to enter is more than 2 times that of conventional slotted pipes of any size and slot opening. This allows more water to enter at much lesser frictional head loss and the efficiency of tube well is improved appreciably.

Better Sand Filtration: Due to specialize manufacturing process, wide range of slot opening is available down to 0.15mm to allow proper slot selection depending upon the size of sand in particular area. This gives better sand control and reduced pump maintenance and longer tube well life.

Energy Saving: Due to reduce frictional head losses and increased discharge, the pump load reduces the power required to pump same quantity of water. Power saving of around 20-25% is observed.