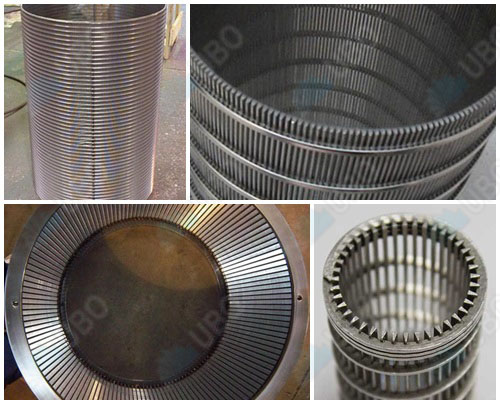

| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Wedge Wire Screen |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

Wedge wire drum screens are made from V shaped profile wire, which is spirally wound around a cage of longitudinal support rods. Each intersection point of these wires is fusion welded, with an unique welding process. The pitch of winding gives different spacing between two adjacent turns of wire. This spacing gives passage for water to enter. The entire process is completed on fully computerized machines. V Wire Screen offers great strength, precision, long service life and a wide range

The screen can be used in food processing, waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an auger or screw press to separate solids from liquids in food, waste water, minerals and industrial grit/chips from coolant.

1.Drum screen mesh is not easy to jam.

2.Smooth operation, low noise.

3.Simple structure, convenient maintenance.

4.Sieve tube can be closed, airtight dust easily.

5.The whole machine has high reliability, one-time investment is less.

6.Adopts special mesh, high screening efficiency, long service life.

SS 304 wedge wire Rotary drum screen

High mechanical load capacity

No form closure connection that would allow vibration of the profiled bars

Automated welding process for high-precision manufacturing

Perfectly adjusted screen basket profiles

Available for all screens

Surface finishing as required

|

Model

|

Mixed Juice Capacity (t/hr)

|

Drum Diameter (mm)

|

Drum Length (mm)

|

Drive (KW)

|

Feed (inlet) Size

|

Discharge (outlet)Size

|

Approx. Mass (kg)

|

|

WT610

|

40

|

600

|

1000

|

1.5

|

DN100

|

DN150

|

535

|

|

WT615

|

73

|

600

|

1500

|

1.5

|

DN100

|

DN150

|

650

|

|

WT1015

|

99

|

1000

|

1500

|

2.5

|

DN150

|

DN200

|

1050

|

|

WT1018

|

132

|

1000

|

1800

|

2.5

|

DN150

|

DN200

|

1170

|

|

WT1518

|

165

|

1500

|

1800

|

4.0

|

DN200

|

DN250

|

1775

|

|

WT1521

|

214

|

1500

|

2100

|

4.0

|

DN250

|

DN300

|

1940

|

|

WT1824

|

264

|

1500

|

1400

|

5.5

|

DN250

|

DN300

|

2130

|