| Category: | Sieve Bend Screen |

| Material: | stainless steel 304,304L,316,316L,321,430 or as per your request. |

| Properties: | sieve bend screen |

| Application: | water-treatment,beer brewing,water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant,refining & petrochemical |

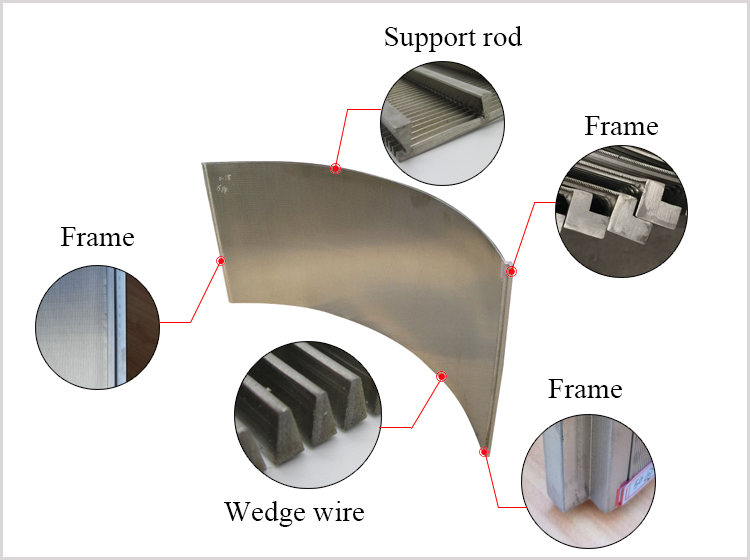

The Looped wire sieve bend screen panel for food processing of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. The dsm sieve bend screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

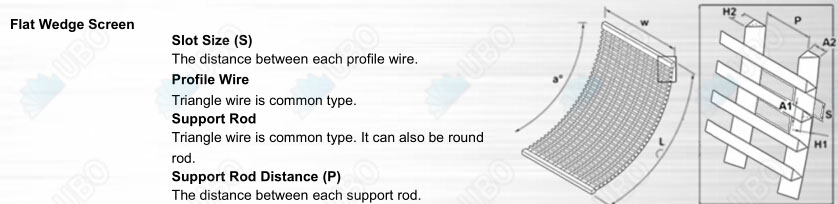

Looped wire sieve bend screen panel also known as side hill screens, parabolic screens,rundown screens, gravityscreens and DSM screens, can be custom designed to separate solids from liquids in various applications including food processing, pulp and paper, waste water cleanup, surface water intakes,corn wet milling, coal preparation, and gold recovery.SS Wedge Wire Sieve Bend Screens are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.A SS Wedge Wire Sieve Bend Screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A SS Wedge Wire Sieve Bend Screens has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Used in industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc.

Used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load.

Used for fiber removal in Starch industry.

Looped wire sieve bend screen panel for food processing is easy to penetrate, having good wear-resisting and corrosion resistance. With Trapezoidal cross-section, even gap, stable welding quality, large opening area, long life time, high strength and high load capacity, it can be made into various shapes. The dimensions, wire diameter, slot and frame structure can be customized.

Looped wire sieve bend screen panel |

|

| Material: | Low carton, low carton galvanized steel (LCG), steel treated with plastic spraying, stainless steel (304,316etc.) |

| Wedge Wire (mm): | Width : 1.50 1.80 2.30 3.00 3.30 3.70 |

| Height : 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 | |

| Support Rod (mm): | Width : 2.30 3.00 3.30 3.70 |

| Height : 2.70 3.60 4.70 5.60 6.30 | |

| Width: | from 1 inch -----45 inch. |

| Length: | Max 6 meters. |

| Slot size | Slot size |

| Radian: | 120º,60º,45º as your request |