| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel |

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

Chip Wringer Oil Screens are used in chip processing centrifuges to separate residual machining fluids (coolants and oils) from metal chip waste (swarf). Significant cost reduction results from reclaiming machining fluids. In addition, a drip-free metal waste product commands a premium market price.

UBO supplies a wide variety of chip wringer screens for manufacturers of chip processing equipment (OEMs) including Ajax Tocco (Premelt), Automet, Mayfran International (Reclamet), Inter-Source Recovery, Prab, National Conveyors, Chip Systems International, and others.

Screens are made using UBO’s custom wedge profile bar wire in a variety of screen sizes and slot openings. Our precision laser cut support rods provide for consistent slot openings. Welded construction makes our chip wringer screens the most durable screens on the market.

1) We use wedge-shaped profile wire in order to make the slot v-shaped. It can stop the impurities very well.

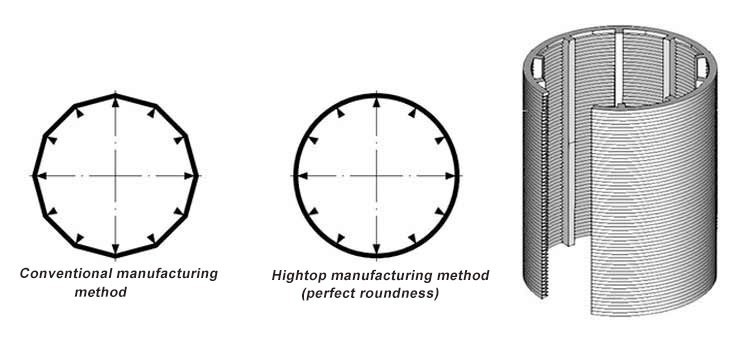

2) The wedge wire was welded on the support wire well-proportioned and have perfect roundness. Ensure the screen have bigger filter area and non obstructive, avoid the high concentration of impurities.

3) After work for a period of time, the filter can be back flush.It can use for many times.

1) Continuous opening has greatly increased the water flow area, so offers a better contact with the aquifer.

2) V-type profile of the structure to avoid clogging and ensure smooth flow.

3) Continuous long-term effective use of the pore.

4) Trapezoidal filter pipe offers a solid structure, high porosity, and accurate poring.

5)Trapezoidal wire filter pipe is easy for washing, long service life, safe, reliable, comprehensive and low cost.

Chip Wringer Oil Screens are widely used in mineral processing, coal processing, food processing, water treatment, petrochemical industry, architecture industry, as well as many other applications involving liquid & solids separation.

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

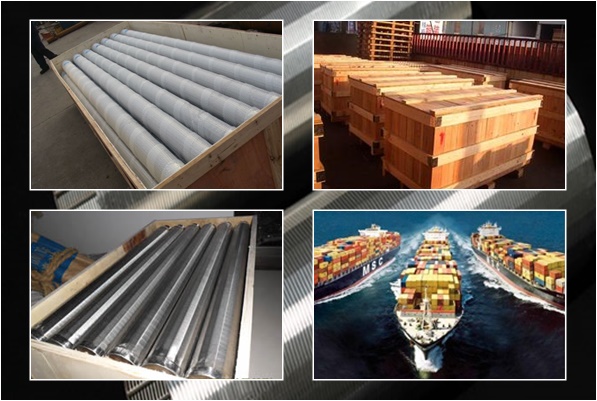

| Packaging Detail: | Provide for ease of transport and safety of packaging,If there are special requirements to be arranged |

| Delivery Detail: |

15-20 days after Signed a contract after receipt of the advance |