| Category: | Sieve Plate Screen |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | sieve plate screen |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

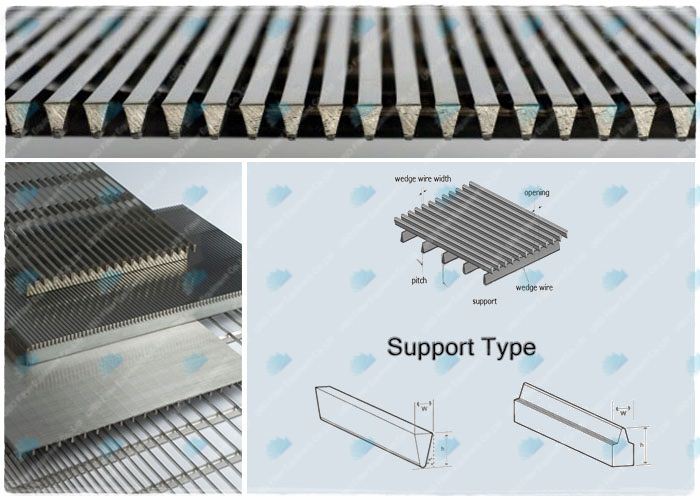

Flat welded wedge wire panels offer a perfectly flat and smooth surface with rectangular openings. Flat Wedge Wire Screen Panels can be constructed using rectangular support rods or round support rods. Flat Wedge Wire Screen Panels can be designed to maximize the open area, strength and wear life to suit any application. Welded Wedge Wire Screens are made from V shaped profile wire, with an unique welding process.

Stainless steel oil flitered nozzle can be fixed on the filtering equipment for the filteration of water petrol resin and other medium. Also it can be used in the water treatment, water softhening, conversion of sea water into fresh water, the filter of food chemistry.

This wide range of wedge wire screens with slot widths from 0.05mm (50 microns) and open areas from 2% through to 40.0% provides solutions for many filtering and separation applications.

They are either fabricated in flat panels with V-sectioned profiled wire arranged in a parallel form and resistance welded to a number of support cross rods or by winding a continuous V-sectioned extruded wire helicoidally onto support bars in the form of a cylinder and welded at each intersection.

The composition of wires and supports can be of different shapes, sizes and materials for different applications where temperature, pressure and applicable conditions prevail such as abrasion and corrosion.

One of the important features of wedge wire screen for filtering and separation is the continuous aperture or “slot”, which automatically provides a large open area guaranteeing a very low pressure drop through the filtering surface with a low tendency to blind or clog.

“Slot widths” are very precise, but more so with looped wedge wire. This type being used for starch screens for the extraction of corn starch

Due to the wires being wound close together and the large number of welds, wedge wire screens are inherently strong and able to provide extended life in such areas as industrial waste treatment.

The continuous aperture and triangular wire section ensures there are only two particle contact points, which minimizes the risk of blinding and clogging.

| Wedge wire screen panel | |

| Material: | AISI304/316/316L,Galvanized low carton. |

| Wedge Wire (mm): | Width : 1.50 1.80 2.30 3.00 3.30 3.70 |

| Height : 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 | |

| Support Rod (mm): | Width : 2.30 3.00 3.30 3.70 |

| Height : 2.70 3.60 4.70 5.60 6.30 | |

| Round : 2.50mm -- 6.0mm | |

| Slot /opening Size | 0.10 -- 6.00mm ,also can be customized as your request. |

| Lengt | Can be customized as your request |

| Width | 25mm -- 1200mm. |

| Note: Other specifications can be customized according to your requirement. | |