| Category: | Wedge Wire Screen Cylinders |

| Material: | SS304 316 316L Low carbon galvanized,Duplex steel etc. |

| Properties: | wedge wire screen |

| Application: | Oil Well Filtration |

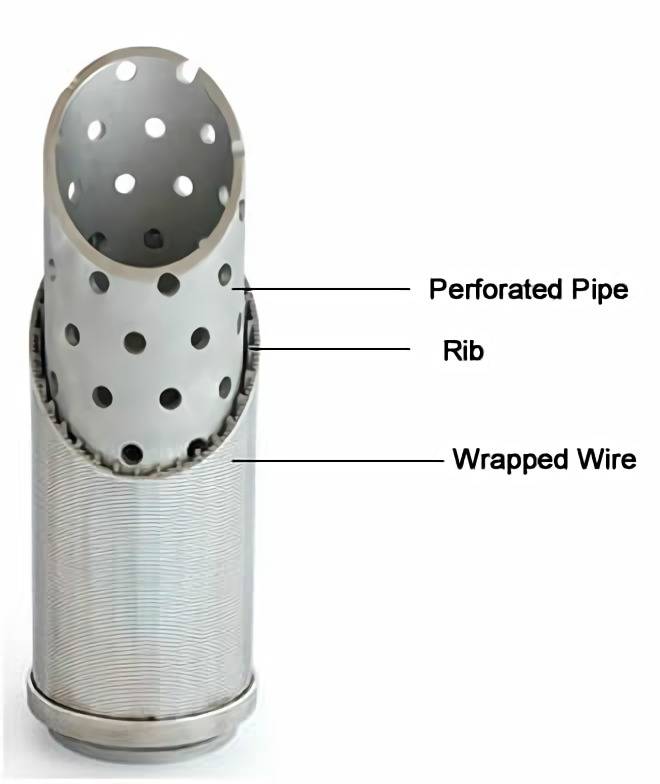

At the core of cutting-edge well completions lies the remarkable Wire Wrapped Screen, a fusion of precision engineering and intelligent design. Comprising a wire-wrapped jacket enveloping a perforated pipe, this innovative solution redefines filtration and performance standards.

V wire mesh wires, artfully helical, elegantly wind around the vertical ribs, each point weld-crafted with precision. This v wire screen design serves a trio of crucial functions: a formidable defense against sand plugging, an intuitive self-cleaning mechanism, and an adept flow friction reduction agent. The very contours of these wire screens are sculpted to diminish the risk of sand intrusion, ensuring uninterrupted operation.

In the realm of well completions, the Johnson Sand Screen Pipe emerges as a stalwart companion, ready to augment performance. Whether as a stand-alone champion or in tandem with gravel-packed completions, this screen tube exudes strength and slot precision. A larger inflow area, compared to conventional slotted liners, emerges as a catalyst for maximal production. Its presence not only guarantees exceptional strength but also ushers in a new era of accurate slot openings.

1. The V Wire Wrapped Screen Tube (Johnson screen tubes) creates a continuous slot, which can avoid blockage and make sure of unimpeded water.

2. The V Wire Wrapped Screen Tube (Johnson screen tubes) has a wider open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under great pressure, so it can control sand better, which can increase the water yield and prolong service time of the well.

3. Wire and support rods are all-welded, which makes the Wedge wire screen pipe (Johnson screens) more robust and longer life.

4. The longitudinal support rods and the continuous slot make the Wedge wire screen pipe (Johnson screen well tubes) have more excellent pressure-resistant performance.

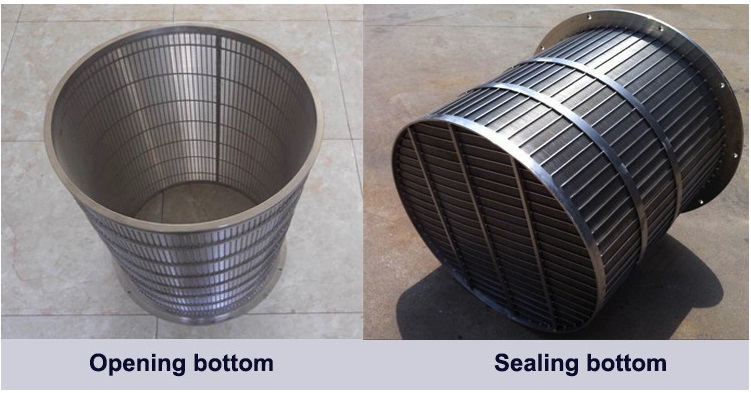

5. Specifications and end connections of the Wedge wire screen pipe (Johnson screens) can be fabricated according to customers’ requirements.

|

Surface profiles

|

Support profiles

|

Min.diam. in mm

|

Min. slot width in mm

|

|

10S

|

Q25

|

21

|

0.10

|

|

11S

|

22S or Q35

|

23

|

0.03

|

|

12S

|

22S

|

30

|

0.05

|

|

12S

|

Q25

|

23

|

0.03

|

|

12S

|

Q35

|

30

|

0.05

|

|

18S

|

22S or Q35

|

30

|

0.05

|

|

18S

|

Q25

|

25

|

0.03

|

|

18S

|

D45

|

300

|

0.20

|

|

18S

|

10x3

|

300

|

0.20

|

|

22S

|

22S or Q35

|

45

|

0.10

|

|

22S

|

D45 or 10x3 or 25x3

|

300

|

0.20

|

|

28S

|

Q35

|

215

|

0.20

|

|

28S

|

D45 or 10x3 or 25x3

|

300

|

0.20

|

|

34S

|

Q35

|

300

|

0.20

|

|

34S

|

D45

|

300

|

0.20

|

|

34S

|

10x3 or 25x3

|

300

|

0.20

|

|

42S

|

Q35 or D45

|

300

|

0.20

|

|

42S

|

10x3 or 25x3

|

300

|

0.20

|

|

Outside diameter in mm

|

Number of support profiles

|

|

30

|

8

|

|

45

|

10

|

|

57

|

12

|

|

70

|

18

|

|

85

|

18

|

|

97

|

20

|

|

110

|

24

|

|

137

|

30

|

|

164

|

36

|

|

215

|

48

|

|

268

|

48

|

|

305

|

40

|

|

380

|

48

|