| Category: | Centrifuge Screens&Baskets |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | centrifuge screens and baskets |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

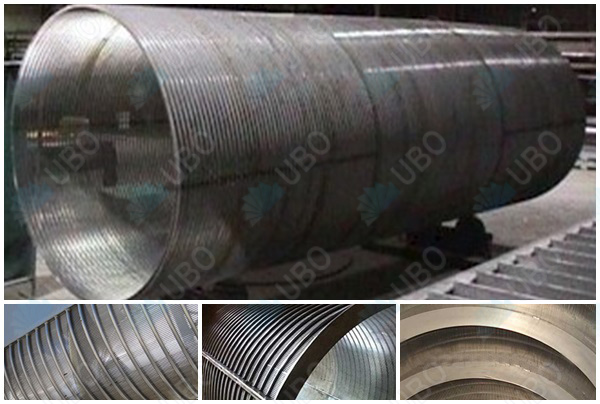

Stainless steel rotary screens are designed to self clean, with wedge wire tubes supporting and reinforcing the structure. Our stainless steel rotary screen and Trommel Screens are produced to work uninterruptedly. This maintains higher efficiency and productivity whilst at the same time minimising energy consumption. Making the benefits of installing Rotary Drums Screens for your waste water screening needs from Gap Technology a definite must.

Rotary Drum Screens are used to mechanically separate liquids from solid particles. Gap Technology offer a wide range of Rotary Drum screens and Rotary Wedge Wire Screens / Trommel Screens for industrial waste water screening applications to our large and varied customer base throughout the United Kingdom and across Europe.

The wedge wire bar rotary drum screen provide more sufficient opening than the perforated metal baskets. It is stronger and can bear heavy loading pressure than the woven mesh filter baskets. The wedge wire basket can work with both benefits of the perforated and woven mesh filter elements and avoid the shortcomings. It is stronger, has more aperture and pressure differential levels can be achieved by variety of the slotting. Also it is economic.

GTS Series wedge wire screen drum screen utilize Mechanical method, compose a screen surface by sieve bar form into pore. Classify by its weight 3 joint shaft inside trommel is higher than surface, to push up big size material so as to increase classify rate. And the inclination will help it advance, enter crusher finally. Size smaller pore will down through the pore and acquire the final product.

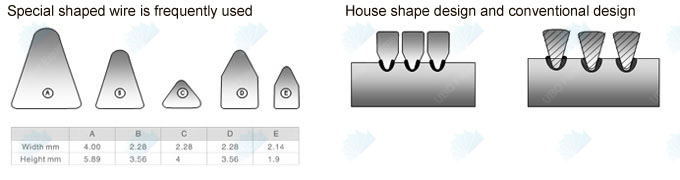

| Specification (wedge wire): | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |