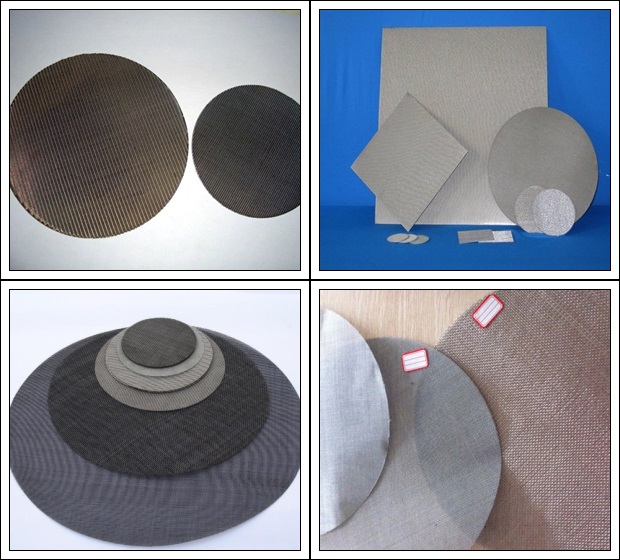

| Category: | Leaf Filters |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | leaf filters |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

Our Vertical Leaf Filters are standard equipped filters, that can be used for numerous filtration processes. Both models are pressure filters with vertical filter leafs.

Our vertical leaf filters are available with Horizontal or Vertical tank execution.

Filters can be utilized for dry or wet cake discharge in a completely closed system.Thanks to it’s unique construction, the filter tank can be easily retracted making the filter plates accessible for the removal of the filter cakes. Vertical Leaf Filters are suited to processes with a high volume and a high solid content. All Vertical Leaf Filters can be supplied in automated versions.

It's commonly used for the progress of distillation, sorption evaporation and filtration to clear up the fog drip and liquid form in petroleum, chemical, fertilizer, medicine, dye, metallurgy, machinery, construction, shipping, environmental protection, textile and other industries.

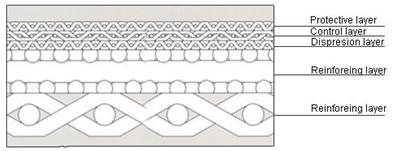

a. Complex structure, high filtering precision

b. Large dirt holding capacity, long service life time

c. Good corrosion resistance and pressure resistance

d. Increased flow quantity per unit area

e. woven type stainless steel mesh, with homogeneous pore distribution, high strength, and easy to clean.

Once the precoating stage is completed the process slurry is pumped into the filter, the forming cake is retained on the leaves and the filtrate flows to further processing.

When the solids are fine and slow to filter a body-aid is added to the feed slurry in order to enhance cake permeability. However, it should be kept in mind that the addition of body-aid increases the solids concentration in the feed so it occupies additional volume between the leaves and increases the amount of cake for disposal.

Likewise, for all those applications when the cake is the product, precoat and filter-aid may not be used since they mix and discharge together with the cake.

Please refer to the section on Pressure Filters for further details on precoating and the addition of body-aid.

Once the filtration cycle is completed air or gas is blown into the vessel and the slurry heel that surrounds the leaves is pushed and displaced downwards until it reaches the lowest part of the leaf stack. At this point the remaining heel slurry is evacuated back to the feed tank by a special dip pipe that is located at the very bottom of the vessel so that the vessel is empty from slurry.

|

Mesh

|

Wire dia (mm)

|

Material (AISI)

|

|

12*64

|

0.58/0.40

|

304 ,316

|

|

24*110

|

0.36/0.25

|

304 ,316

|

|

14*88

|

0.50/0.33

|

304 ,316

|

|

30*150

|

0.18/0.14

|

304 ,316

|

|

40*200

|

0.14/0.11

|

304 ,316

|

|

50*250

|

0.10/0.071

|

304 ,316

|

|

80*700

|

0.06/0.05

|

304 ,316

|

|

165*800

|

0.071/0.04

|

304 ,316

|

|

200*1800

|

0.05/0.03

|

304 ,316

|

|

325*2300

|

0.03/0.025

|

316L

|

|

400*2800

|

0.03/0.02

|

316L

|