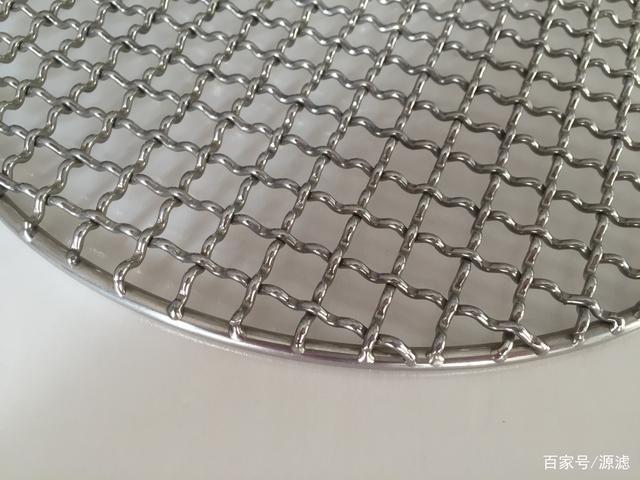

What is a

stainless steel woven mesh? As the name suggests, the stainless steel woven net is woven on a loom, which is very similar to the weaving method of cloth. The wire has two directions, namely, bending wire and closing wire. Braided wires are usually manufactured on rolls and then cut or formed into the desired shape and size.

Woven materials can form very stable but flexible filter media, almost like fabric or cloth.

The material can be made of wires of different thicknesses, or woven into different patterns according to specific applications.

Due to its labor-intensive production, braided wire is often used in more complex or more technical applications than welded wire mesh.

Typical applications of woven mesh:

-Screening and sizing

-Need for beautiful architectural applications

-Pest control and livestock cages

-Ventilation net

-Wastewater

-Filters for air, fuel, oil and hydraulic systems

The advantages of woven nets:

-Customization: Because the media is woven, there are many customizations available, such as opening size, specific weaving type, and even the thickness of each thread. These changes will affect prices and usage, but there are many ways to get the specific results required for filtering.

-Ventilation: Woven wire mesh can achieve stable, uninterrupted flow in ventilation applications. You can allow air in and out of an area, or you can use it to prevent impurities from entering containers that require ventilation. It can also be used as a pre-filter, which will provide a good flow rate while extending the life of the fine filter located downstream.

-Precise opening/precision: This material is woven on a very precise high-speed loom and uses high-quality wires with strict dimensional tolerances. This results in a very precise, accurate and repeatable aperture.

-Flexibility: Wire braided but not welded together allows the material to be formed into various shapes and specifications without damaging the material or reducing accuracy.

-Production: Using typical sheet metal production techniques, this material can be cut, shaped or made into almost any shape imaginable. The final product can be small and simple, or large and complex.

-Cleanable/reusable: The nature of the material is metal, which can provide surface filtration instead of depth filtration, so the filter can be cleaned and reusable, and the service life is longer than typical disposable filters.

-Harsh environment: Woven wire mesh can provide fine filtration in environments that other fine filters cannot withstand. The specifications of the woven wire mesh can meet the requirements of low micron level in applications involving high pressure, high temperature or corrosive chemicals for good performance.