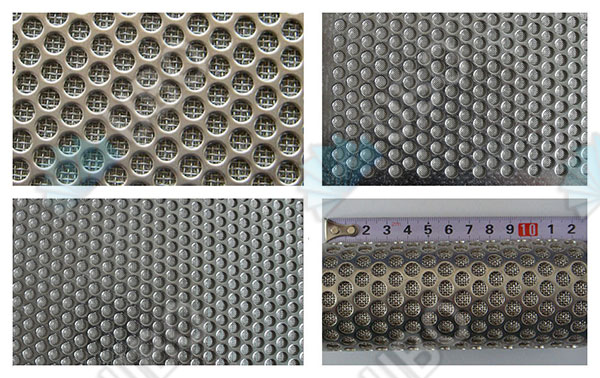

Brief Introduction of Perforated Plate

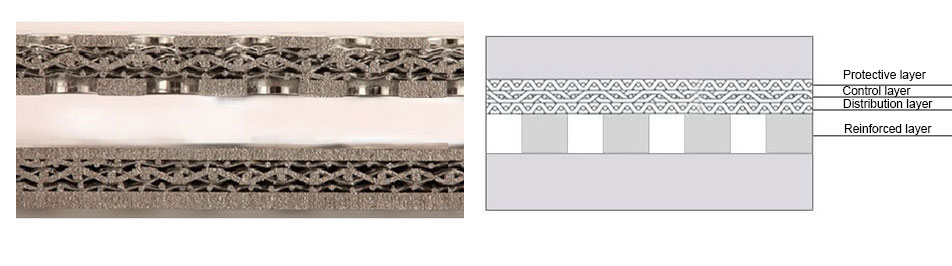

Punching sintered mesh is a sintered mesh in which a porous plate and a base-layer plain weave are sintered together. Punching plate can be used according to need different thickness, flat woven mesh can be one or more layers. As a perforated plate to do support, composite network compressive strength and high mechanical strength. Both sintered together have good air permeability of the plain weave, and the mechanical strength of the perforated plate. Can be processed into a cylindrical, disc, chip, cone filter. Widely used in water treatment, beverage, food, metallurgy, chemical and pharmaceutical industries.

Characteristics of perforated plate sintered mesh

(1) good strength: As a perforated plate support, with the sintered net in the highest mechanical strength and compressive strength.

(2) easy to clean: As a result of the surface filter material, with the characteristics of cleaning, especially for backwash.

(3) easy processing: suitable for cutting, bending, stamping, stretching, welding and other processing technology.

(4) high temperature: can withstand 480 ℃ high temperature.

(5) corrosion resistance: As a result of the SUS316L, 304 materials, so strong corrosion resistance.

(6) Filtration accuracy: Filtration accuracy of a total of 1μ-100μ, have a reliable filter performance.

(7) Stability: As the upper and lower layers of the screen to do protection, plus diffusion solidification of the sintering process is not easy to deformation of the filter.

Use of perforated plate sintered mesh

(1) for very high temperature environment to do the dispersion cooling of the material.

(2) for the gas industry, the application of uniform gas, fluidized steel plate in the industry.

(3) for gas distribution fluidized bed orifice plate material.

(4) for the blast furnace pulverized coal flow is too concentrated and dense phase transport system.

(5) the pharmaceutical industry in the filtration, washing and drying.

(6) a catalyst supporting barrier.

(7) for polyester, oil, food and beverage, chemical fiber products, filtration, but also for water treatment and gas filtration.

| Type | name of accuracy(um) | accuracy of gas(L/min·dm2·1000pa) | bubbling pressure(pa) |

| MSW1 | 1 | 180 | 5300-6000 |

| MSW2 | 2 | 240 | 4300-5000 |

| MSW5 | 5 | 260 | 3000-37000 |

| MSW10 | 10 | 310 | 2700-3300 |

| MSW15 | 15 | 350 | 2000-2600 |

| MSW20 | 20 | 450 | 1800-2300 |

| MSW25 | 25 | 620 | 1400-1900 |

| MSW30 | 30 | 690 | 1200-1700 |

| MSW40 | 40 | 420 | 1000-1500 |

| MSW50 | 50 | 850 | 900-1200 |

| MSW70 | 70 | 900 | 700-1100 |

| MSW100 | 100 | 1080 | 650-1000 |

| MSW150 | 150 | 2600 | 500-800 |

| MSW200 | 200 | 2800 | 450-600 |

Note: The standard size: 500mm × 1000mm 600mm × 1200mm 1000mm × 1200mm

Standard thickness: 1.7mm or so

Standard material: 316L can also be used 304

Filtration performance for the reference data, order to test qualified shall prevail