| Category: | Water Strainer & Nozzle |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

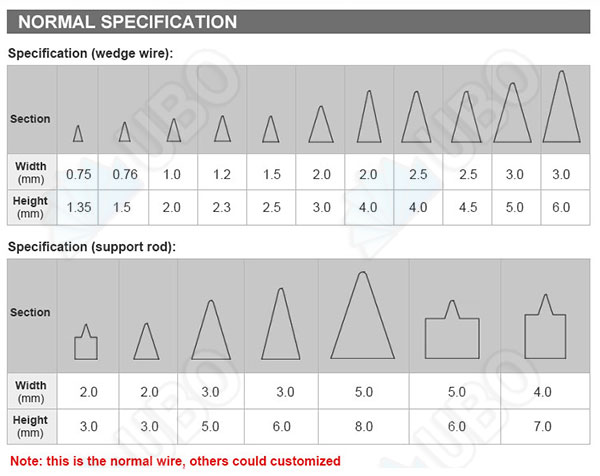

| Properties: | wedge wire screen |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

Stainless steel filter nozzles manufactured by wrapping a shaped wire around an internal array of longitudinal rods.The wire and rod, generally made from carbon or stainless steel are joined by resistance welding. Screen sections are usually twenty feet long. Commonly referred to as continuous slot or wire wrap screen, this product was originally developed to overcome problems associated with cable tool wells drilled in fine grained.

The wedge wire screen filter nozzle can be fixed on the filtering equipment for the filteration of water petrol resin and other medium. Also it can be used in the water treatment, water softhening, conversion of sea water into fresh water, the filter of food chemistry.

Great mechanical strength

Highly resistant to abrasivity and vibration.

It can hold more pressure and temperature compared to the perforated sheet screen.

Longer screen life.

Larger useful area than that of the standard perforated sheet screen.

The wedge wire screen can be used in any of INOXPA filters.

The wedge wire screen is assembled to the filter body by clamp, this allows an easy and quick disassembling for cleaning.

It is possible to clean the wedge wire screen with a reversed flow (back flushing).