Chemical slotted wedge wire screens are the ideal filter medium for the production of paints, resins, inks, dyes, drugs, chemicals, and petrochemicals. Filtration plays a crucial role in fluid systems as it eliminates unwanted particles from the liquid, ensuring the product's integrity and keeping the system clean. If debris is left unchecked, it can cause defects or damage, making it necessary to increase filtration.

Many of the finished goods in the chemical industry are made using the same process equipment. As a result impurities from one process stream could negatively impact neighboring systems which can lead to unwanted contamination, additional clean in place measures, product loss, and decreased revenue. Efficient filtration systems positioned in critical chemical process locations can help mitigate risk by increasing particulate removal efficiency while improving effluent quality and reducing necessary maintenance.

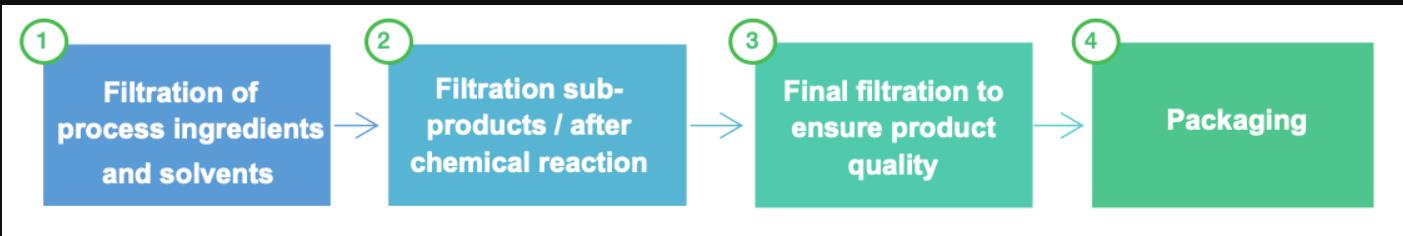

The initial stage of chemical production involves the filtration of process ingredients to ensure the purification of solvents and the elimination of unwanted particulate or pollutants from both organic and inorganic products. This is crucial in maintaining the efficiency of the chemical reaction and reducing the production of sub-products. To achieve this, we recommend the use of Centrifugal baskets and screen support grids. These are commonly used as the support grid provides precise separation of chemical particles, while centrifugal baskets offer a more accurate aperture. Given the industrial application, it is advisable to use reinforcing mesh with abrasive coatings to ensure that the screens can withstand exposure to chemicals and other pharmaceutical products.

In chemical reactions, sub-products are often produced and it is important to retain them to improve the purity of the final product. To achieve this, we recommend using stainless steel pleated filter elements. These filter elements are effective in removing deformable particles that may be present during the reaction. Additionally, the inherent positive charge within the filter media makes it an ideal solution for removing colloids.

By using stainless steel pleated filter elements, you can ensure that the sub-products are retained and the final product is of high purity. This is crucial in industries such as pharmaceuticals, where purity is of utmost importance. The use of these filter elements can also help to reduce the amount of waste generated during the production process, making it a more sustainable solution.

To ensure the purity and quality of the product before conditioning and packaging, it is recommended to perform a final filtration step. For this purpose, we suggest using our sintered filter elements. These filter elements are designed to provide high-quality filtration and are ideal for use in the final stages of the production process. They are capable of removing even the smallest particles and impurities, ensuring that the final product is of the highest quality. With our sintered filter elements, you can be confident that your product will meet the highest standards of purity and quality.

The use of screens is crucial in the petrochemical industry, particularly during chemical processing. These screens are utilized not only during the mixing of chemicals but also for media retention, de-sulfuring procedures, hydro-treating processes, and other applications. Whether you aim to enhance manufacturing efficiency or improve product quality, we are committed to partnering with you and utilizing our technical expertise in chemical processing to help you achieve your objectives.

Our manufacturing techniques enable us to provide customized solutions in various forms of slot wedge wire screens, and we can process materials down to the nanometric scale.

Wedge Wire Support Grids

Wedge Wire Centrifugal baskets

Wedge Wire filter tubes

Stainless steel Pleated filter elements

Sintered filter medias

Wedge Wire Filter Housing