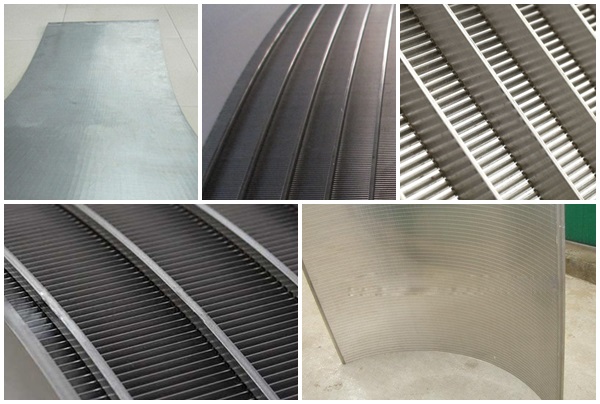

Our company produces stainless steel sieve is a metal mesh structural elements used for sieving filter. Widely used in many industries sieving, filtration, dehydration, mud and other operations. It has high strength, rigidity and load carrying capacity, can be made into various shapes rigid sieving filter means.

This product uses advanced welding processes. Slit screen surface has the highest screening efficiency, the strongest earthquake tensile strength, minimal maintenance requirements and longest service life.

Material: 302,304,304L, 316,316L such as stainless steel wedge wire.

Features: Stainless steel fused sieve element is composed of a support bar and screen bars two parts.

Support bar can be round wire also may be triangular or trapezoidal silk, screen bars is a triangle silk (v Type Wire). Slot size precision, high filtration precision; with rugged, high temperature, corrosion resistance, good mechanical properties, long life, safety reliability etc characteristic. It can be used in a variety of media filtering and screening.

Our company produces series of sieve bend screen. Sieve have a good filtration and dehydration in solid-liquid separation. Sieve is mainly used in sewage treatment, water purification laundry, poultry, fisheries, fruits and vegetables wastewater treatment industry.

We can according to your filtering requirements and filter material for you to produce the different width, length, and width of the seam and wedge wire size. We design your screen has a long service life and requires minimal maintenance costs. Materials include stainless steel, galvanized, you can also add flanges on request.

UBO can create the most accurate and durable sculping best sieve bend screen surface, vibrating sieve, arc (rotary) vibrating sieve, sieve basket, and also can more than 0.05mm material processing. Its wire geometry is good, cutting sharp, good sculping properties, not only to ensure maximum efficiency, but also to the maximum to avoid clogging the sieve. Due to material for excellent wear resistance and unique processing technology, greatly reduce the number of swap the screen surface for the user, reduce production costs, improve work efficiency.

Sieve is sieving important working parts to complete the sieving process, each screening machinery must choose a sieve in line with work requirements. Various characteristics of materials, sieve various parameters of different structures, materials and screening machine are on the shaker screening capacity, efficiency, run rough and have a certain influence life, different materials, different places should be used in different sieve, in order to achieve the best results sieved. Sieve should have sufficient strength, a higher opening rate and easy clogging properties. When the shaker vibration, sieve through different shapes and sizes of materials, materials size under the effect of vibration force, the size of the different materials are separated to achieve the purpose of classification.