| Category: | Wedge Wire Screen Cylinders |

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Screen |

| Application: | water treatment, Sugar,Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc |

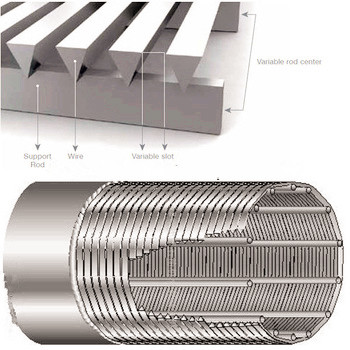

The Wire Wrapped Screen is composed of rod strips and V shaped wires through manufacturing on specialized welding machine.The rib strips and V shaped wires will be welded by resistance welding, has enough welding strength, equally slot gap, high corrosion resistance, large filter area, good permeability, simple structure.

1.Up to 60% or more free open entry area

2.Installation possible to depths of 2000 m

3.Smaller diameters can be drilled as gravel packing is not necessarily required

4.The slogs can't be clogged due to wedgeshaped surface wires

5.high quality , lower price , fastest delivery

deep well , water well , geothermal well , tube well , oil and gas exploration well , irrigation well , resident and industrial using well

The well point screen for dewatering is an incorporate.

These incorporate a self Jetting head with a non-return ball valve, a stainless steel slotted filter screen, a G.I inner drain pipe and a top coupling which threads to standard 1 ½" (40 mm) riser pipe.

The serrations on the jet head render penetration, even through hard grounds, easy.

Specially designed slots of stainless steel screen, allows maximum water flow with minimum pressure drop and prevents passage of even fine material.

The screen eliminates clogging due to corrosion or deterioration due to chemical action.

It has a reverse self cleaning design to void choking. If you have interest in our stainless steel well point screen,please feel free to contact us.

The welded stainless steel water well screen is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time, water well screen have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

|

V-Wire Wrap Screen

|

|

|

Material:

|

Low carton, low carton galvanized steel (LCG), steel treated with plastic spraying, stainless steel (304,316etc.)

|

|

Wedge Wire (mm):

|

Width : 1.50 1.80 2.30 3.00 3.30 3.70

|

|

Height : 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

|

Support Rod (mm):

|

Width : 2.30 3.00 3.30 3.70

|

|

Height : 2.70 3.60 4.70 5.60 6.30

|

|

|

Round : 2.50mm -- 6.0mm

|

|

|

Diameter ranging

|

from 1 inch -----45 inch.

|

|

Length:

|

lengths up to 6 meters.

|

|

Slot size:

|

0.10, 0.15, 0.20, 0.25, 0.30,....., 3.00 also achieved upon request.

|

|

Note: Other specifications can be customized according to your requirement

|

|