| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel |

| Properties: | wedge wire screen |

| Application: | Filtration |

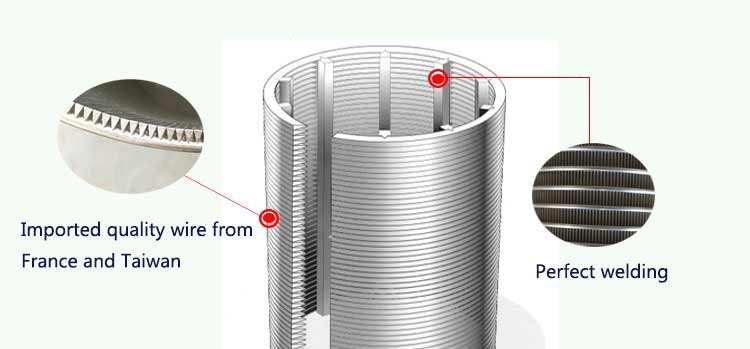

radiused screen cylinder is used in a wide variety of processes across several industry sectors. We use state-of-the-art manufacturing techniques that place our products at the cutting edge of wedge wire screen construction. Flat panels can be designed and manufactured according to customer specifications and come in a wide range of grades - from fine gap screens for small particle sizes to heavy duty screens for heavy load applications.

1.The V-shape section plane of Wedge wire screen pipe (Wedge Wire screens) creates the continuous slot, which can avoid blockage and make sure of the unimpeded water.

2. The consecutive slot of Wedge wire screen pipe (Wedge Wire screens) have wider open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can control sand better, which can increase the water yield and prolong service time of the well.

3. Wire and support rods are all-welded, which makes the Wedge wire screen pipe (Wedge Wire screens) more robust and longer life.

4. The longitudinal support rods and the continuous slot make the Wedge wire screen pipe (Wedge Wire screens) have more excellent pressure-resistant performance.

5. Specifications and end connections of Wedge wire screen pipe (Wedge Wire screens) can be fabricated according to customers’ requirements.

The stainless steel screen are mainly used for the water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant ,sewage treatment and other industries,water, oil or gas filter and other filtration equipment

1.We use wedge-shaped profile wire in order to make the slot v-shaped.It can stop the impurities very well.

2.The wedge wire was welded on the support wire well-proportioned and have perfect roundness. Ensure the strainer have bigger filter area and non obstructive, avoid the high concentration of impurities.

3.After work for a period of time, the strainer can be back flush.It can use for many times.

|

Size

(inch)

|

O.D

(mm)

|

Slot

(inch)

|

Collapse Strength

(Psi)

|

Tensile Weight

(Ton)

|

Wrap(thick*deep)

(mm)

|

Rods

(mm)

|

|

4

|

117

|

0.04

|

395

|

6

|

2.2*3.0

|

3.8mm/22

|

|

4

|

114.3

|

0.04

|

395

|

6

|

2.3*3.0

|

3.8mm/22

|

|

6

|

168.3

|

0.04

|

252

|

8

|

2.3*3.5

|

3.8mm/32

|

|

8

|

219.1

|

0.01

|

399

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

8

|

219.1

|

0.02

|

370

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

8

|

219.1

|

0.04

|

323

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

10

|

273.1

|

0.01

|

206

|

11

|

3.0*5.0

|

3.8mm/50

|

|

10

|

273.1

|

0.02

|

191

|

11

|

3.0*5.0

|

3.8mm/50

|

|

10

|

273.1

|

0.04

|

167

|

11

|

3.0*5.0

|

3.8mm/50

|