| Category: | Sintered Metal Mesh Filter |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Sintered filter |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

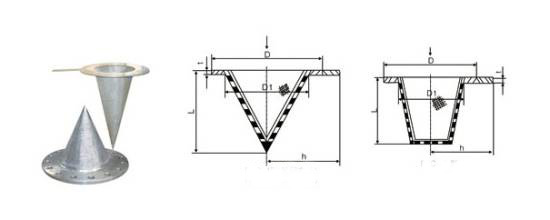

Sintered mesh Cone filter is made of Sintered 5-layer or multi-layer stainless steel wire mesh laminates, it takes the advantages of good permeability, high holding dirty capacity, large filter area, long service life, high temperature resistance and corrosion resistance, and cleanable, can be used for many times, it is widely applied in the filtration system of petroleum and chemical industry.

1. Used in food and beverage industry (milk powder, tea, coffee and etc).

2. Used in chemical and pharmaceutical industry (pharmaceutical products,plastic Recycling

and Precision sieving of powders and etc.)

3. Used in petrochemical industry.

4. Used in water treatment system.

5. Used in aerospace industry.

1. Strength: As fourth and fifth layers do support, with high mechanical strength and compressive strength.

2. Easy to clean: As a result of surface of the filter material, having means for cleaning characteristics, especially suitable for backwashing.

3. Easy processing: suitable for cutting, bending, stamping, drawing, welding and other processes.

4. High temperature: 480 °Ccan withstand high temperatures.

5. Corrosion resistance: As a result of SUS316L, 304 materials, the corrosion resistance.

6. Filtration: Filtration range of 2μm-200μm, has a reliable filter performance.

7. Stability: Because there are two layers to do to protect the screen, plus solid melting diffusion sintering process which make filters is not easily to deform.

|

TYPE |

Nominal Micron

um |

Working Micron

um |

Air Permeability

L/min*cm2*pa |

Bubble Point Pressure

Pa |

|

XL-SW1 |

1 |

6-7 |

|

5300-6000 |

|

XL-SW2 |

2 |

8-9 |

(1-6)*10-4 |

4300-5000 |

|

XL-SW5 |

5 |

11-13 |

(6-10)*10-4 |

3000-3700 |

|

XL-SW10 |

10 |

16-18 |

(6-10)*10-4 |

2700-3300 |

|

XL-SW15 |

15 |

24-26 |

(1-6)*10-3 |

2000-2600 |

|

XL-SW20 |

20 |

28-32 |

(1-6)*10-3 |

1800-2300 |

|

XL-SW25 |

25 |

34-36 |

(6-10)*10-3 |

1400-1900 |

|

XL-SW30 |

30 |

40-45 |

(6-10)*10-3 |

1200-1700 |

|

XL-SW40 |

40 |

50-55 |

(1-6)*10-2 |

1000-1500 |

|

XL-SW50 |

50 |

71-80 |

(1-6)*10-2 |

900-1200 |

|

XL-SW70 |

70 |

86-95 |

(6-10)*10-2 |

700-1100 |

|

XL-SW100 |

100 |

110-120 |

≥5*10-2 |

650-1000 |

|

XL-SW150 |

150 |

|

≥5*10-2 |

|

|

XL-SW200 |

200 |

|

≥8*10-2 |

|

|

XL-SW300 |

300 |

|

≥8*10-2 |

|