| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Wedge Wire Screen |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

SS Wedge Wire v wire wrapped water well screen tube (V-shaped wire). The Industrial wedge wire wrapped screen have a robust structure and large open area, as well as accurate slot dimension. At the same time, wedge wire screens pipe have many advantages such as heat-resisting, anti-corrosive, good machine capability,long service life, safety and reliability and so on. It can be used in many kinds of medium filtering.

The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time, Wedge Wire screen have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. Wedge Wire screen can be used in many kinds of medium filtering.

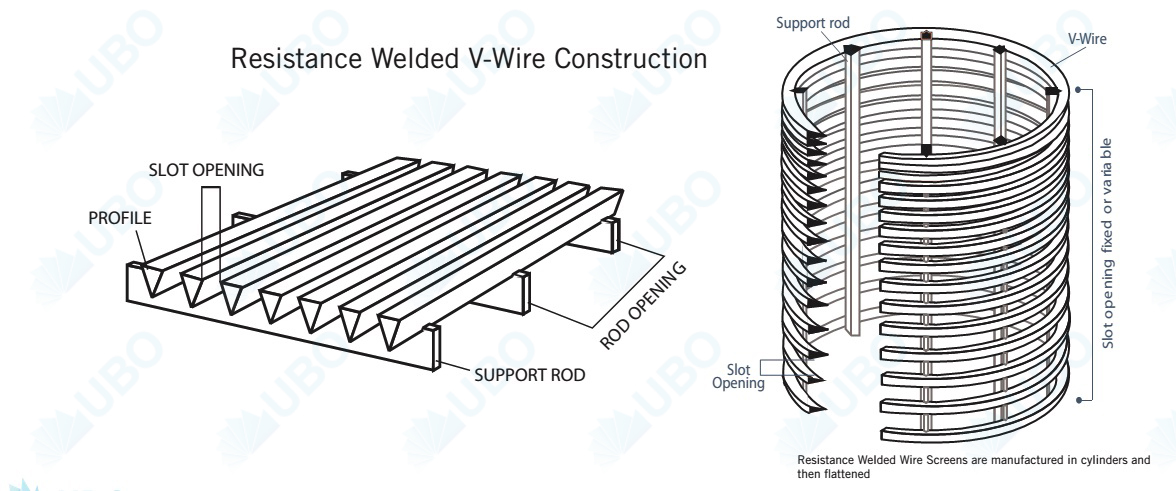

1. Non-clogging construction: The V-shape section plane of wedge wire screens (Wedge Wire type screens) creates the continuous slot, which can avoid blockage and make sure of the unimpeded water.

2. Large Filtering Area: The consecutive slot of wedge wire screens (Wedge Wire type screens) have wider open area,

and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can control sand better,

which can increase the water yield and prolong service time of the well.

3.Long service life Wire and support rods are all-welded, which makes wedge wire screens (Wedge Wire types screens) more robust and longer life.

4.Excellent construction strength: The longitudinal support rods and the continuous slot make the wedge wire screens(Wedge Wire type screens) have more excellent pressure-resistant performance.

5.Specifications and end connections of wedge wire screens(Wedge Wire screens) can me fabricated according to customers’ requirements.

|

wedge wire |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 |

|

support rod |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters |

|

Diameter |

from 25mm to 1200mm. |