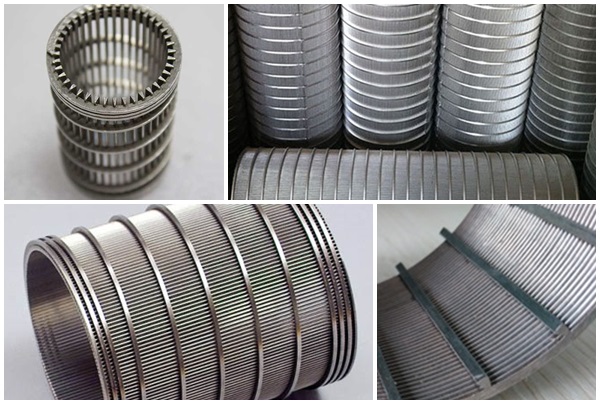

| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel |

| Properties: | wedge wire screen |

| Application: | Filtration |

Profile wire Screens consist of V-shape profile wire and the longitudinal support rods. each intersecting point of these wires is fusion welded. So Profile wire Screens has sturdy constriction and good mechanical property. The V-shape section plane can avoid blockage, and make sure of the unimpeded water. The continuous slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so Profile wire Screens can filter sand better. Meanwhile ,the slot size can be changed according to the real condition of the customer requirements

1.Chemical industry

2.Oil field, gas field

3.Mining

4.Textile, dyeing, paper-making industry

5.Municipal engineering

6.Nonferrous metal

7.Agriculture

8.Sea water transportation

9.Thermal engineering

10.Buried drainage pipe, cable dredge pipe

1.It has higher strength, stiffness, impact resistance than plastic pipe.

2.Corrosion resistance on both surfaces, it has same corrosion resistance with plastic pipe.

3.High work temperature, low thermal conductivity, heat insulation for outer wall is not required when it is used in winter, and no moisture condensation when it is used in summer.

4.Smooth and neat inner wall, no scaling, head loss is 30% lower than steel pipe.

5.Pipe connection adopts electric melting connection which is the mature technology, The electric melting joint has strong axial tension resistance. The pipe fittings have many specifications.

6.Light weight, easy transportation and construction. Overall reliability for pipes is high.

7.Low cost, health and non-toxic, it is the best substitute for galvanized pipe.

The color is generally black. Also can be decided according to customer negotiation.

The inner and outer surface of the tube should be glossy and smooth. Tiny pits and bumps are allowable. Air bubble, breach, decomposition color line and obvious wound are not allowable. The both ends of the tube should be cut flat.

|

Screen Size

|

ID

|

OD

|

Female thread dismeter

|

||||

|

in

|

mm

|

in

|

mm

|

in

|

mm

|

in

|

mm

|

|

2

|

51

|

2

|

51

|

25/8

|

67

|

23/4

|

70

|

|

3

|

76

|

3

|

76

|

35/8

|

92

|

33/4

|

95

|

|

4

|

102

|

4

|

102

|

45/8

|

117

|

43/4

|

121

|

|

5

|

127

|

5

|

127

|

55/8

|

143

|

53/4

|

146

|

|

6

|

152

|

6

|

152

|

65/8

|

168

|

7

|

178

|

|

8

|

203

|

8

|

203

|

85/8

|

219

|

91/4

|

235

|

|

10

|

254

|

10

|

254

|

103/4

|

273

|

113/8

|

289

|

|

12

|

305

|

12

|

305

|

123/4

|

324

|

133/8

|

340

|

|

14

|

356

|

13 1/8

|

333

|

14

|

356

|

-

|

-

|

|

16

|

406

|

15

|

381

|

16

|

406

|

-

|

-

|

|

20

|

508

|

18 3/5

|

476

|

20

|

508

|

-

|

-

|

|

Profile Wire

|

|

|

|

|

|

|

|

|

|

Width(mm)

|

1.5

|

1.5

|

2.3

|

2.3

|

1.8

|

3.0

|

3.7

|

3.3

|

|

Height(mm)

|

2.2

|

2.5

|

2.7

|

3.6

|

4.3

|

4.7

|

5.6

|

6.3

|

|

Support Rod

|

|

|

|

|

|

Round

|

|

Width(mm)

|

2.3

|

2.3

|

3.0

|

3.7

|

3.3

|

Ø2.5~Ø5mm

|

|

Height(mm)

|

2.7

|

3.6

|

4.7

|

5.6

|

6.3

|

|