| Category: | Cone Filter&Strainer |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | stainless steel filter |

| Application: | Filtration,fuel Filter,Hydraulic Filter,Petroleum, chemical, food, environmental protection, heavy machinery, film, medicine, water treatment, high te |

Main filter media of cone filters is stainless steel weaving wire cloth and multiple layers sintered wire mesh. On the basis of features and advantage of disc filter, cone filter increases filter area and easily discharges the material. The size is available at the customers’ request.

Pressure filters for fine filtration in hydraulic steering equipment;Oil and fuel filters

ressure and vacuum filters (disc, cell and drum filters);As porous media for fluidised beds;Pre-coat filters;Filter candles;Protection of steering and fuel injection nozzles

Insulation / sound attenuation (e.g. aircraft engines);In the following industrial sectors;Air and space travel;Automotive industry;Petrochemicals;Chemical and pharmaceutical;industry/Biotechnology;Medical science;Food and beverage industry;Plastics industry;Environmental technology

1. Strength: As fourth and fifth layers do support, with high mechanical strength and

compressive strength.

2. Easy to clean: As a result of surface of the filter material, having means for

cleaning characteristics, especially suitable for backwashing.

3. Easy processing: suitable for cutting, bending, stamping, drawing, welding and other processes.

4. High temperature: 480 °Ccan withstand high temperatures.

5. Corrosion resistance: As a result of SUS316L, 304 materials, the corrosion resistance.

6. Filtration: Filtration range of 2μm-200μm, has a reliable filter performance.

7. Stability: Because there are two layers to do to protect the screen, plus solid melting

diffusion sintering process which make filters is not easily to deform.

|

flange size (inch )

|

||||||

|

pipe size

|

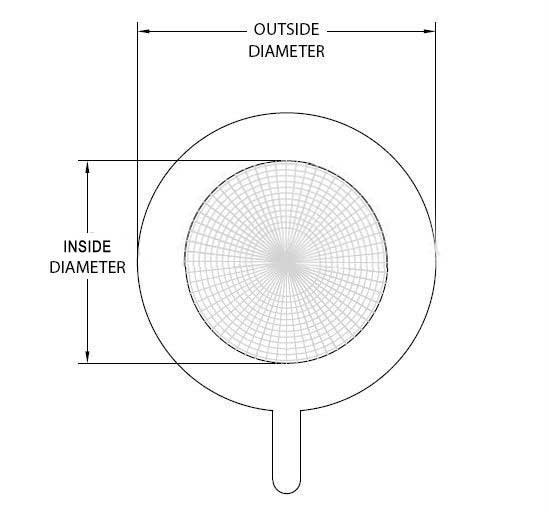

inside diameter

|

outside diameter (class 150-1500)

|

||||

|

500/300

|

300

|

600

|

900

|

1500

|

||

|

3/4

|

5/8

|

2-1/8

|

2-1/2

|

2-1/2

|

2-5/8

|

2-5/8

|

|

1

|

3/4

|

2-1/2

|

2-3/4

|

2-3/4

|

3

|

3

|

|

1-1/2

|

1-1/4

|

3-1/4

|

3-5/8

|

3-5/8

|

3-3/4

|

3-3/4

|

|

2

|

1-3/4

|

4

|

4-1/4

|

4-1/4

|

5-1/2

|

5-1/2

|

|

2-1/2

|

2-1/4

|

4-3/4

|

5

|

5

|

6-3/8

|

6-3/8

|

|

3

|

2-3/4

|

5-1/4

|

5-3/4

|

5-3/4

|

6-1/2

|

6-3/4

|

|

4

|

3-3/4

|

6-3/4

|

7

|

7-1/2

|

8

|

8-1/8

|

|

5

|

4-5/8

|

7-5/8

|

8-1/4

|

9-3/8

|

9-5/8

|

9-7/8

|

|

6

|

5-1/2

|

8-5/8

|

9-3/4

|

10-3/8

|

11-1/4

|

11

|

|

8

|

7-3/8

|

10-7/8

|

12

|

12-1/2

|

14

|

13-3/4

|

|

10

|

9-3/8

|

13-1/4

|

14-1/8

|

15-5/8

|

17

|

17

|

|

12

|

11

|

16

|

16-1/2

|

17-7/8

|

19-1/2

|

20-3/8

|

|

14

|

12-1/4

|

17-3/8

|

18-7/8

|

19

|

20-3/8

|

22-5/8

|

|

16

|

14

|

20-1/8

|

21

|

21-7/8

|

22-1/2

|

25-1/8

|

|

18

|

15-3/4

|

21-1/4

|

23

|

23-3/4

|

25

|

27-5/8

|

|

20

|

17-1/2

|

23-1/2

|

25-1/2

|

26-5/8

|

27-3/8

|

29-5/8

|

|

24

|

21-1/4

|

27-7/8

|

30-1/4

|

30-7/8

|

32-7/8

|

35-3/8

|

|

30

|

27-1/4

|

34-3/8

|

37-1/8

|

37-7/8

|

39-3/8

|

-

|

|

36

|

33

|

40-7/8

|

43-5/8

|

44-1/8

|

46-7/8

|

-

|